We research and develop further - for our customers!

ContactWe research and perfect our products

We conduct research to improve our products and solutions in the interest of our customers and to protect the environment. The results of our research should enable us to offer our customers the best, most effective and energy-saving solutions.

Research DUSTEX®

The research project “Optimized Water Consumption in the Separation of Particulate Matter PM 2.5 by Electrostatic Influence of Water Dispersion Systems” (in short: OPTEB) is being carried out in cooperation with the University of Wuppertal as scientific partner under the auspices of the German Federal Ministry of Education and Research.

The research objective is to achieve a better dust collection effect by electrostatically charging the spray mist and thus saving water. Based on the research results, a new type of water dispersion system is to be developed that is suitable for effectively separating dust particles of small size in a water-saving manner without having to use additives that could potentially have an adverse effect on the environment.

To carry out the project, VSR Industrietechnik GmbH built a 20 m long wind tunnel. A precisely dimensioned, dust-flowing stream of material is conveyed by the fan through the channel, in which several nozzles are installed for dust binding. Behind the nozzle, the intensity of the dust binding effect is determined by means of a laser aerosol spectrometer. Tests are carried out with dusts of various materials.

Research VIBMATIC®

OpVib – Research into the mechanisms of action and effectiveness of the vibration stress relief process for metallic materials by combining experiment and simulation.

The VSR process for the reduction of residual stresses has been known for a long time – its effectiveness is beyond doubt due to the positive experiences of many users.

However, the mechanisms occurring that contribute to stress reduction in components and workpieces have not yet been clearly quantified, and the theoretical background has been discussed in the literature for some time.

The objective of the research project was to provide unequivocal evidence that vibration treatment in accordance with requirements significantly reduces the residual stress state in a specimen and later in a component.

The project was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) as part of the Central Innovation Program for SMEs (ZIM). Since it was not possible to carry out the project with the originally chosen partners, the subprojects were carried out with new partners:

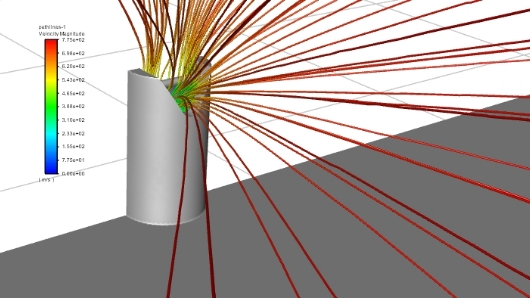

– Simulation in cooperation with the Center for Wind Power Drives (CWD) of the RWTH Aachen, by Prof. Jacobs, Dr. Schelenz and Dipl. Ing. Witter.

– Neutron beam investigation on behalf of VSR by Mr. Dr. Hofmann of the Research Neutron Source Heinz Maier-Leibnitz at the Technical University of Munich in Garching.

The desired proof was to be provided by first determining a simulation guideline and subsequently comparing the results with those of the neutron beam investigation, among other things in order to develop a method for computer-aided analysis of optimized residual stress reduction of components by vibration relaxation.

As close to reality as possible, the commonly used structural steel S355 was chosen as the specimen material. The preparation and handling of the specimens proved to be very laborious during the course of the project, as any external influence could have led to a change in the residual stress state.

The optimum positioning of the specimens and the application of the vibration energy were determined by the simulation model; the specimens were then set up in Garching based on the specifications, radiographed, vibration-treated and radiographed again. At the same time, the simulation calculation was carried out in Aachen.

When the special specimens, which had been welded to increase the residual stress potential, were examined, the neutron beam measurement did not provide any reliable evidence of large differences between the stress states before and after the vibration treatment. The reason for this is assumed to be the superimposed influence of natural relaxation over the comparatively long time required for the overall execution of the test in Duisburg, Berlin and Munich, as well as external influences during the necessary transports.

In contrast, the simulation based on the actually set boundary conditions (welding filler metal and speed, material characteristics, excitation direction, amplitude and frequency) yielded the unambiguous result that vibration treatment relieves the unwelcome residual stresses.

The final comparative investigation of a vibration-relieved and a stress-relieved specimen even showed that the residual stresses in the selected material were better reduced by vibration treatment than by annealing.