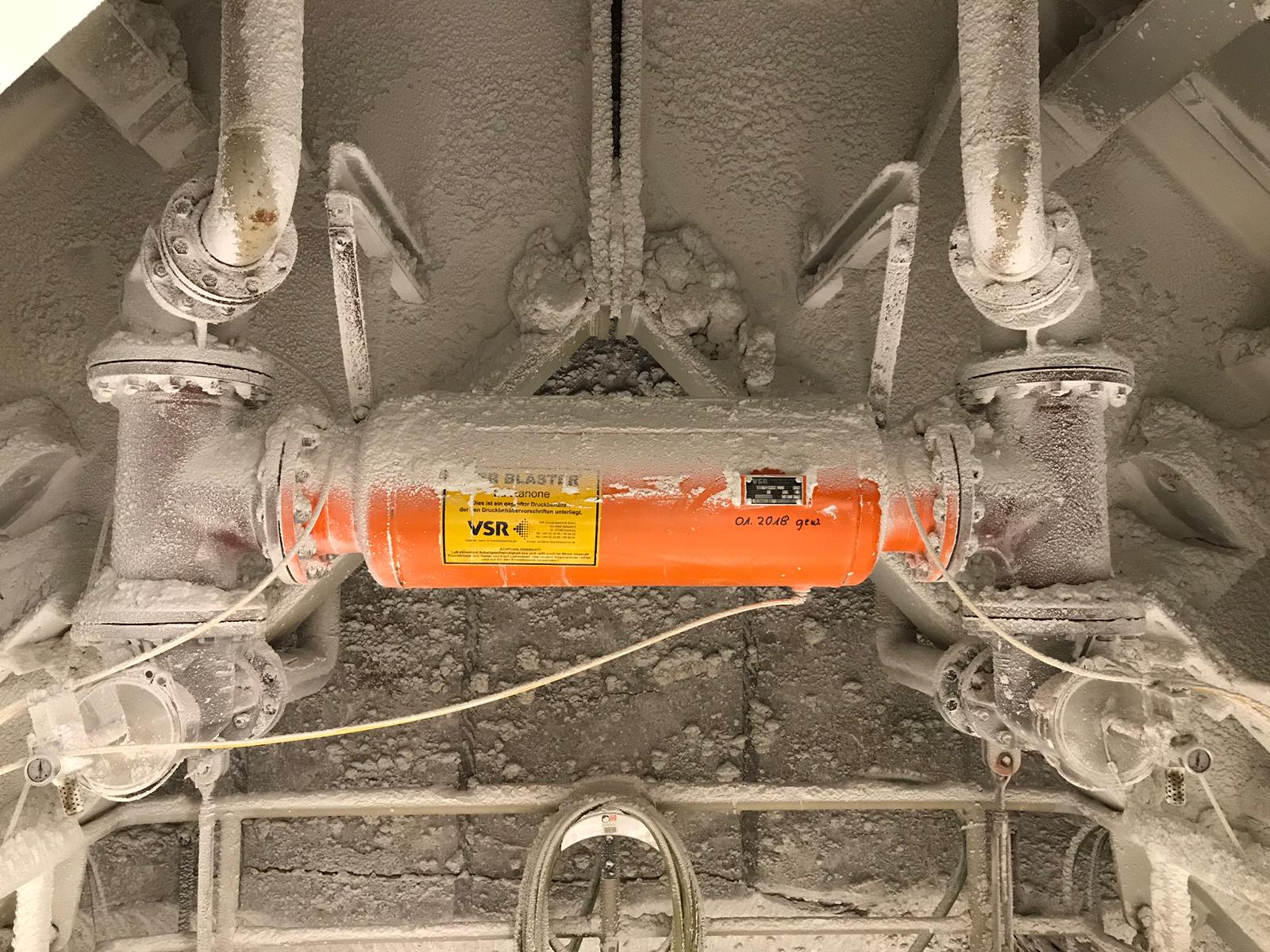

VSR BLASTER®

Air cannons and air injectors

The most efficient way to avoid discharge problems and caking in cold and hot areas, thereby ensuring continuous production.

The solution for your discharge problem

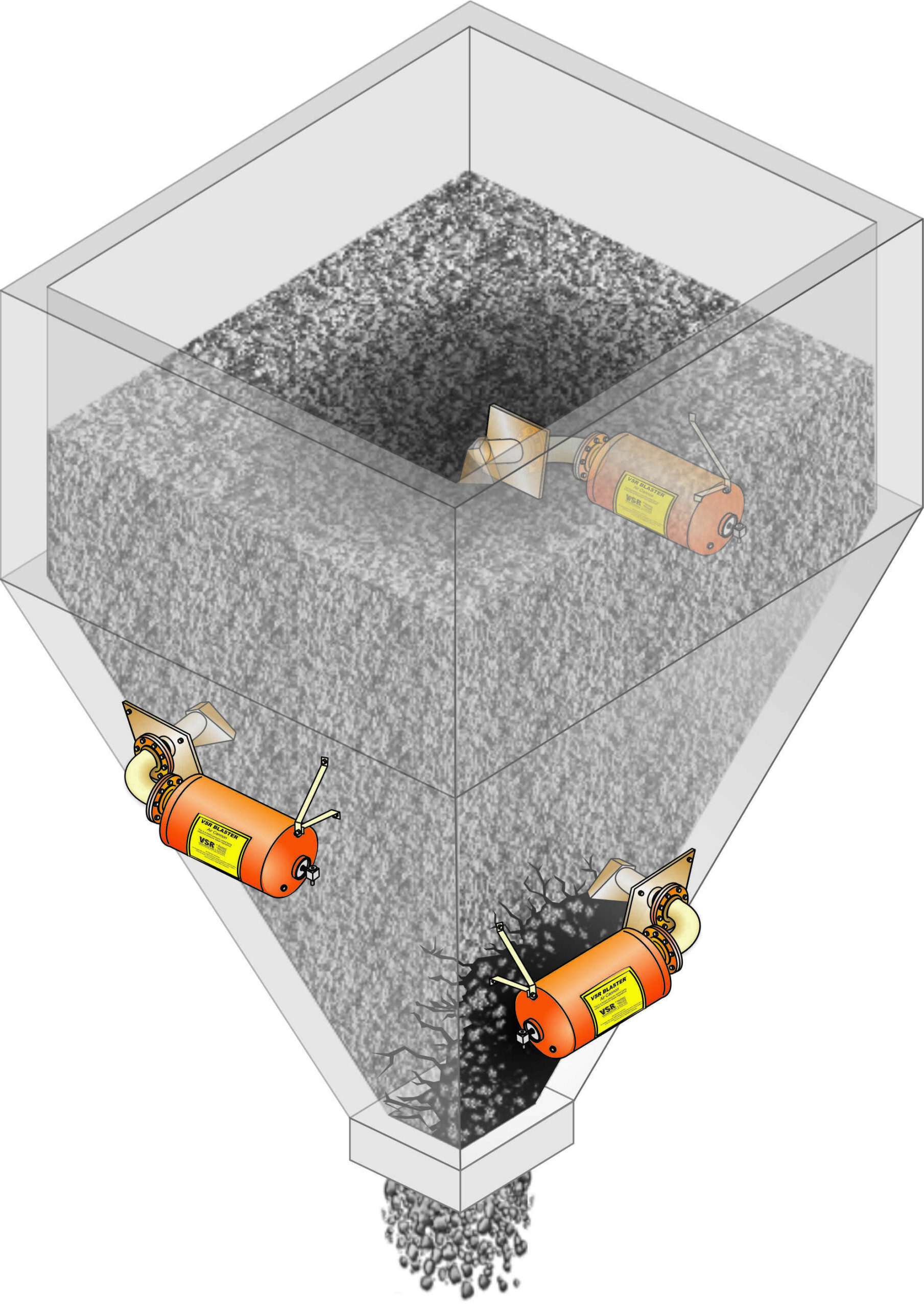

VSR BLASTER® air cannons for pneumatic elimination of discharge problems in silos, bunkers and stockpiles as well for the prevention of build-up and caking in hot and cold areas.

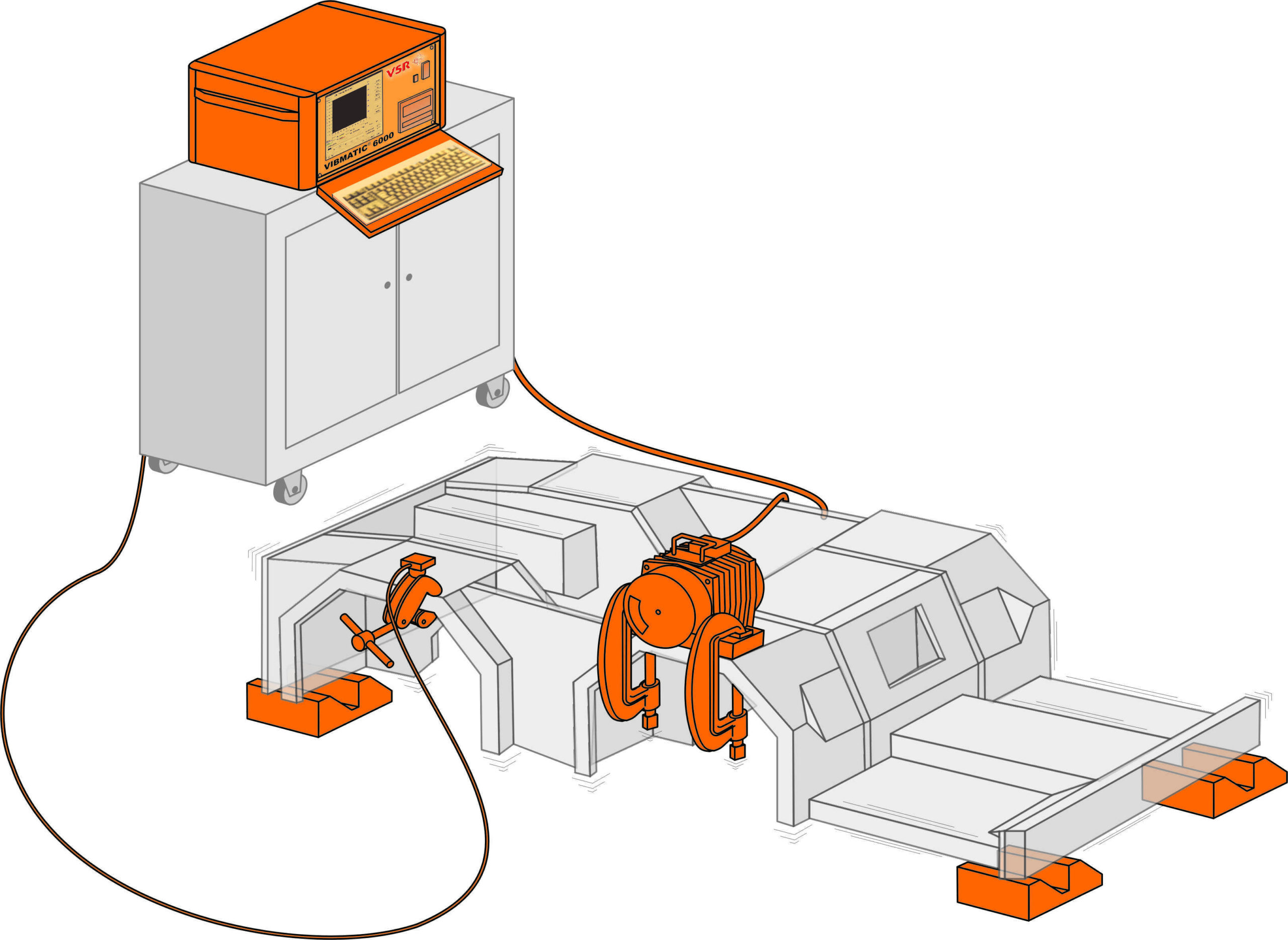

Prevention of discharge problems through superior impulse forces

The high quality of the products, constant advancement and individual design of the air cannon systems have guaranteed maximum effectiveness for over 45 years.

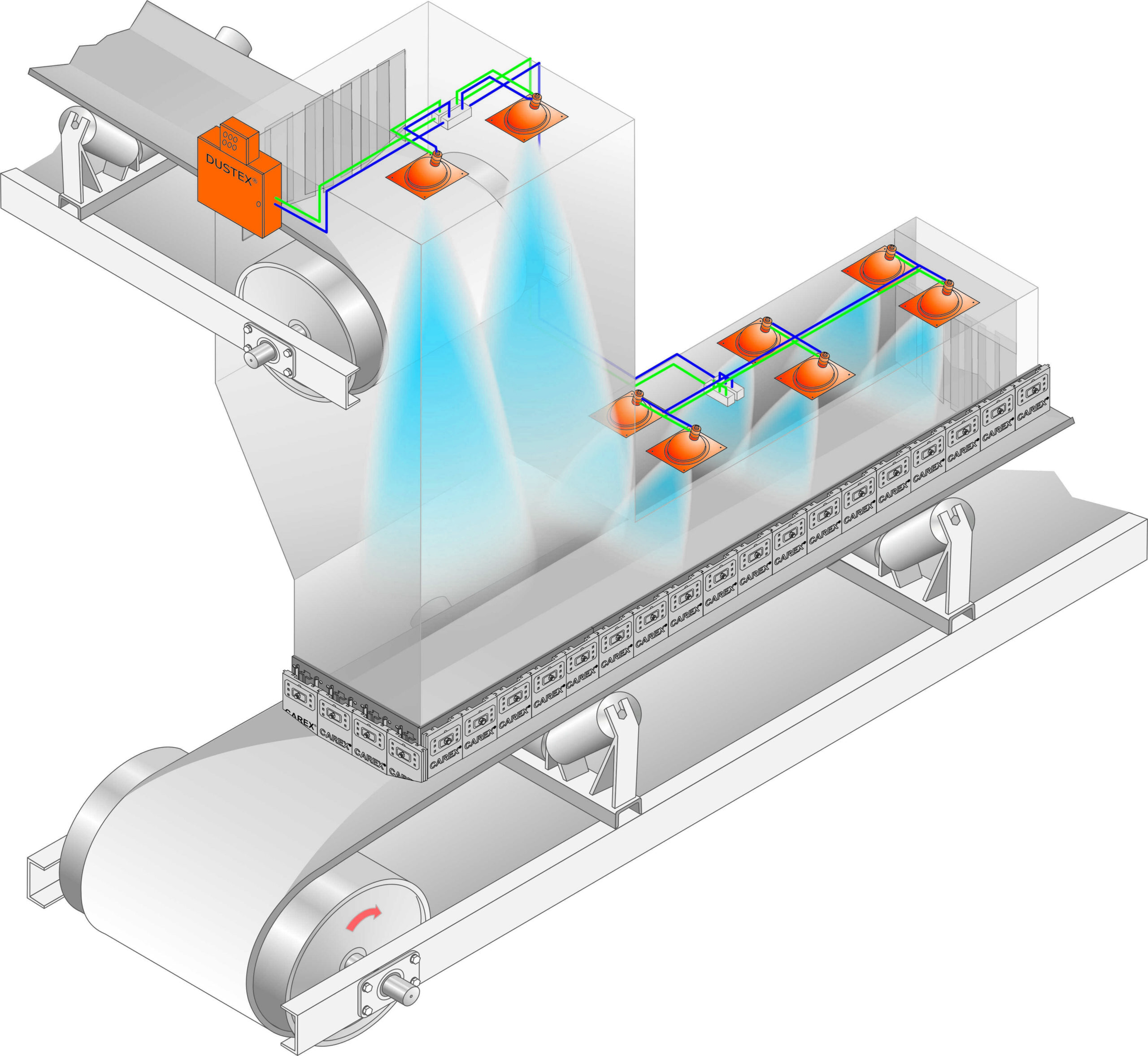

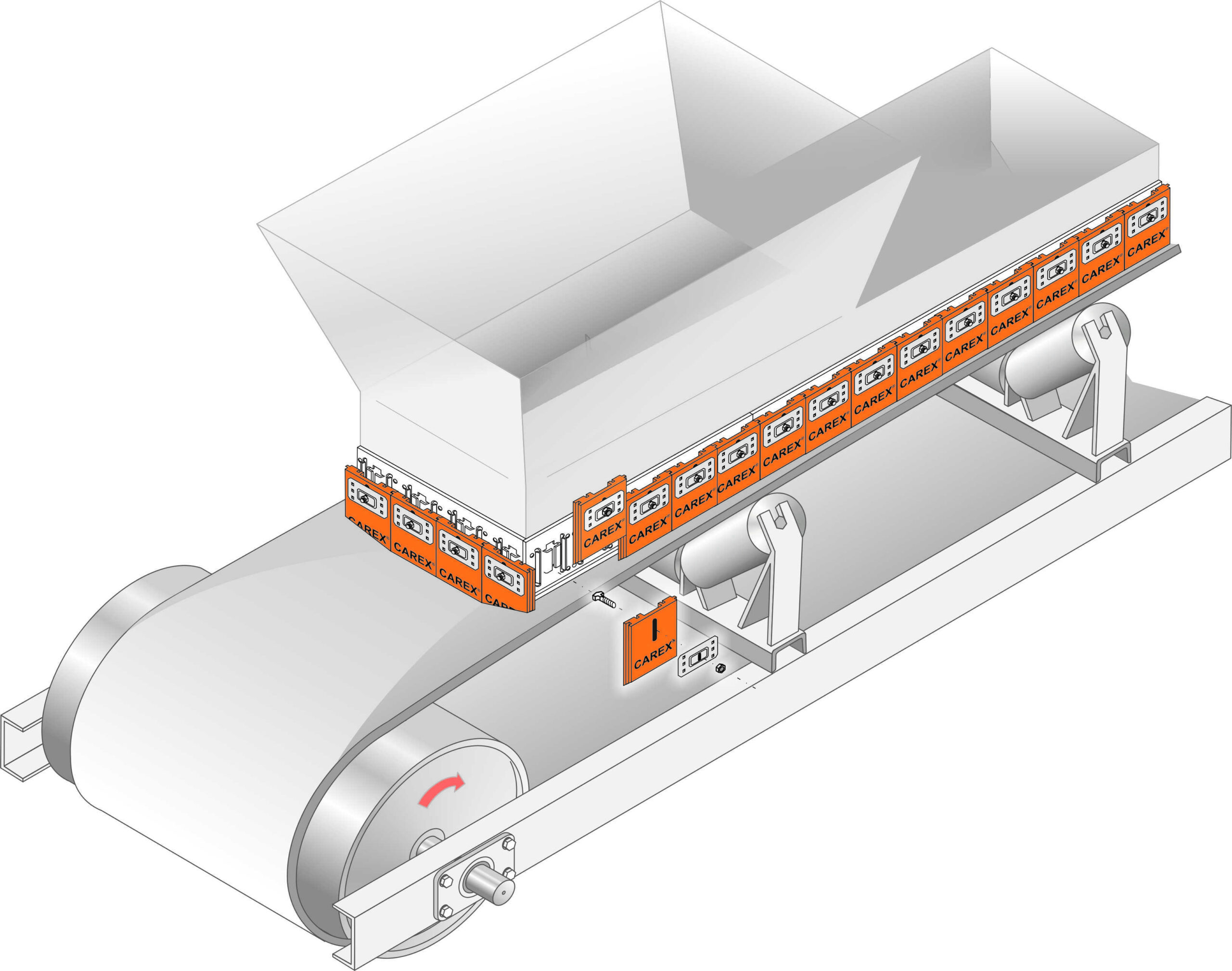

- Elimination of funnel, chimney and bridge forming during storage and handling of bulk materials in silos, bunkers and stockpiles

- Prevention of build-up in chutes and feeding hoppers

- Elimination of build-up and residues from combustion

Innovation

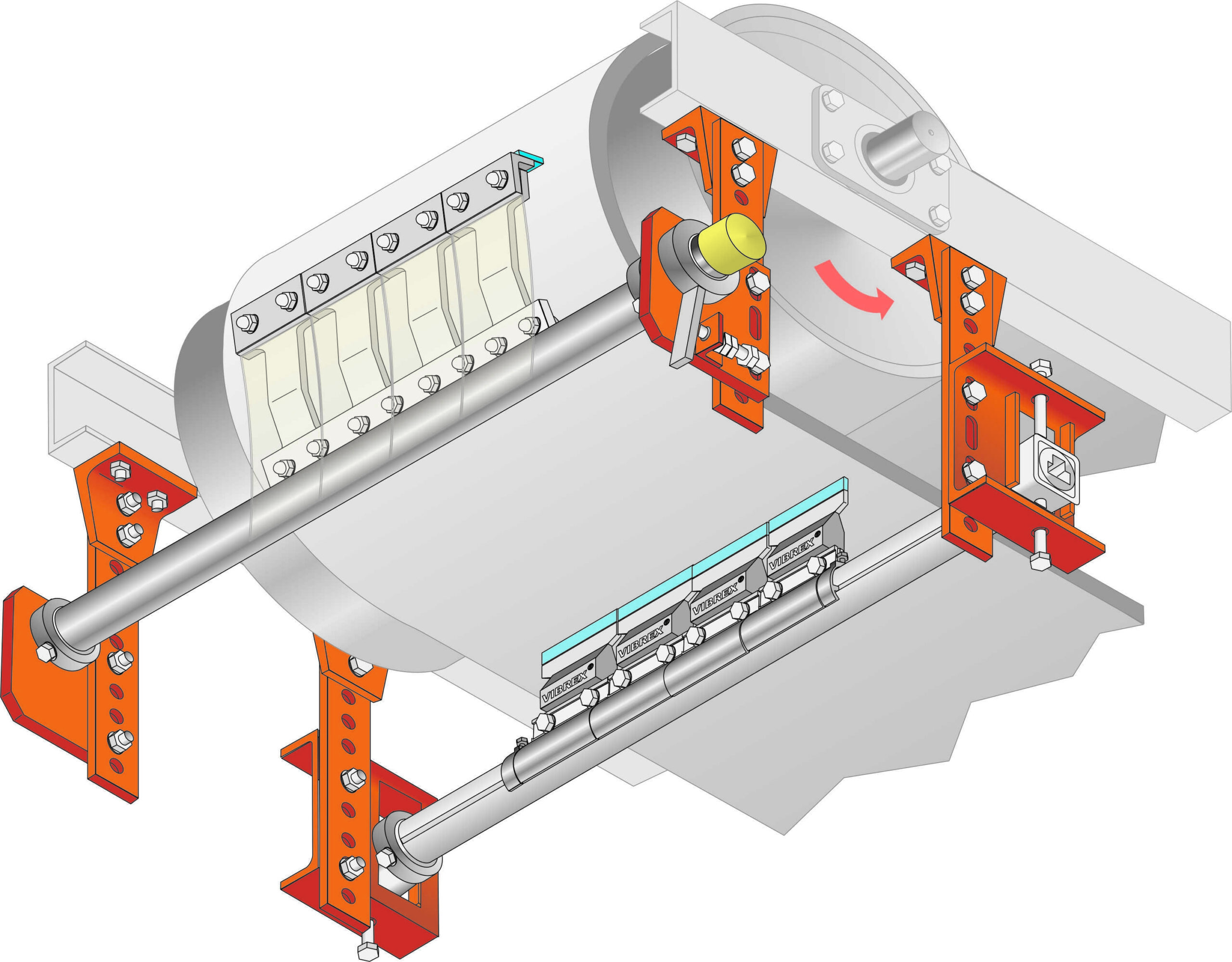

Product innovation in the air cannon area – Rapid Change Nozzle

Our latest innovation is the Rapid Change Nozzle. The advantage of this nozzle is that it can be changed in a very short time from the outside without entering the oven or hopper. The system, which was designed for use in hot areas, can also be operated in cold areas without any restrictions.

6 Advantages of the VSR BLASTER®

The strong air blasts of the VSR BLASTER® air cannons eliminate caking that regularly occurs, for example in heat exchangers or in rotary cement kilns. This ensures optimum heat exchange and material flow.

Simple installation and operation

Low energy consumption with maximum impulse power

Accident safety

Maintenance friendly

Effectiveness guarantee

Individual selection of nozzles

Depending on the application, we use a simple blow pipe, our fan jet angle nozzles, spreader nozzles or sword nozzles regardless if for cold or hot areas.

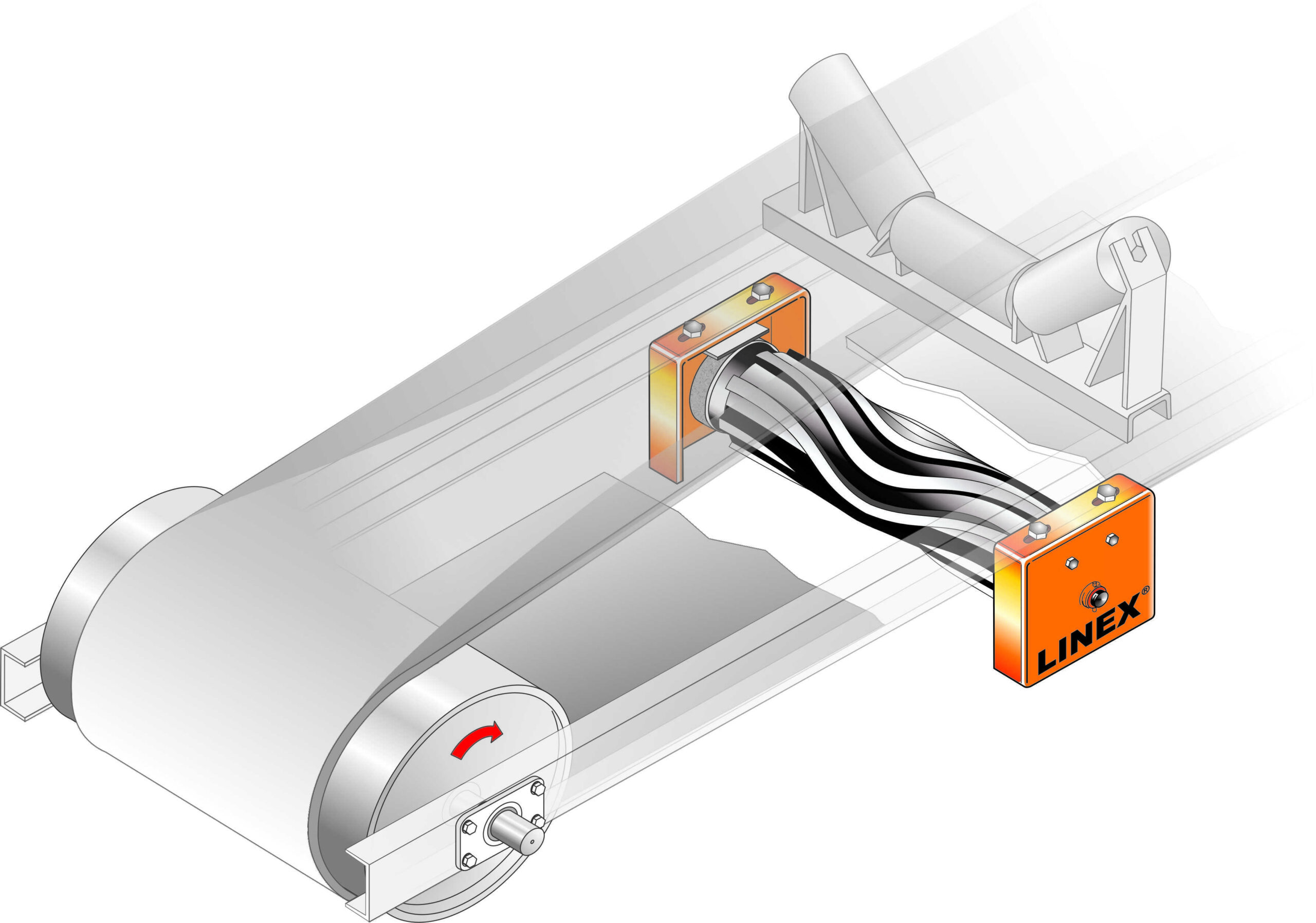

Function of the VSR BLASTER® air cannon

The pneumatic solution for all types of discharge problems

Within milliseconds, the VSR BLASTER® air cannon blasts an amount of compressed air through specially shaped nozzles into critical material zones. The resulting energy from the air blast fluidized the bulk material in the previously critical zones. Material discharge problems or transport difficulties can be eliminated and build-ups can be removed. The high effectiveness of VSR BLASTER® air cannons is based on optimal combination of the components. Due to a specially developed quick exhaust valve, a minimum exhaust time of the piston chamber is achieved. This fact and the relation of the piston area to the blow-out cross-section ensure rapid opening and unhindered discharge of the compressed air from the air cannon.

As a result, the pressure vessel of all VSR BLASTER® sizes is emptied in milliseconds and the maximum possible impulse force is generated.

Contact us. We look forward to hearing from you!

Werner Schüppel

+49 2066 996660 • schueppel@vsr-industrietechnik.de