Wir forschen und entwickeln uns weiter – Für unsere Kunden!

Jetzt kontaktierenWir forschen und perfektionieren unsere Produkte

Wir forschen, um unsere Produkte und Lösungen im Interesse der Kunden und zur Schonung der Umwelt weiterzuentwickeln. Die Ergebnisse unserer Forschungen sollen uns in die Lage versetzen, unseren Kunden die besten, effektivsten und energiesparendsten Lösungen anbieten zu können.

Forschung DUSTEX®

Das Forschungsprojekt „Optimierter Wasserverbrauch bei der Abscheidung von Feinstaub PM 2,5 durch elektrostatische Beeinflussung von Wasserdispersionssystemen“ (in Kürze: OPTEB) wird in Zusammenarbeit mit der Bergischen Universität Wuppertal als wissenschaftlichem Partner unter der Schirmherrschaft des Bundesministeriums für Bildung und Forschung durchgeführt.

Forschungsziel ist es, eine bessere Staub-Abscheidewirkung zu erzielen, indem man den Sprühnebel elektostatisch auflädt und auf diese Weise Wasser zu sparen. Auf Basis der Forschungsergebnisse soll ein neuartiges Wasserdispersionssystem entwickelt werden, das geeignet ist, effektiv und wassersparend Staubpartikel geringer Größe abzuscheiden, ohne dass dazu Additive eingesetzt eingesetzt werden müssen, die möglicherweise umweltbelastend wirken können.

Zur Durchführung des Projektes wurde durch die VSR Industrietechnik GmbH ein 20 m langer Windkanal errrichtet. Ein genau bemessener, staubfömiger Materialstrom wird vom Ventilator durch den Kanal gefördert, in dem mehrere Düsen zur Staubbindung eingebaut sind. Hinter der Bedüsung wird die Intensität des Staubbindeeffektes mit Hilfe eines Laser-Aerosolspektrometers ermittelt. Es werden Versuche mit Stäuben verschiedener Materialien durchgeführt.

Forschung VIBMATIC®

Hier steht eine Subheadline die kurz zusammenfasstOpVib – Erforschung der Wirkmechanismen und Wirksamkeit des Verfahrens zur Vibrationsentspannung für metallische Werkstoffe durch Kombination von Experiment und Simulation

Das VSR-Verfahren zur Reduktion von Eigenspannungen ist seit langer Zeit bekannt – seine Wirksamkeit steht durch die positiven Erfahrungen vieler Anwender außer Zweifel.

Die auftretenden Mechanismen, die zur Spannungsreduktion in Bauteilen und Werkstücken beitragen, sind bisher aber nicht eindeutig quantifiziert worden, und der theoretische Hintergrund wird in der Literatur seit einiger Zeit diskutiert.

Zielsetzung des Forschungsprojektes war die Erbringung des eindeutigen Beweises, dass durch eine anforderungsgerechte Vibrationsbehandlung der Eigenspannungszustand in einer Probe und später in einem Bauteil signifikant gemindert wird.

Das Projekt wurde im Rahmen des Zentralen Innovationsprogrammes Mittelstand (ZIM) vom Bundesministerium für Wirtschaft und Energie (BMWi) gefördert. Da die Durchführung des Projekts mit den ursprünglich gewählten Partnern nicht möglich war, wurden die Teilprojekte mit neuen Partnern durchgeführt:

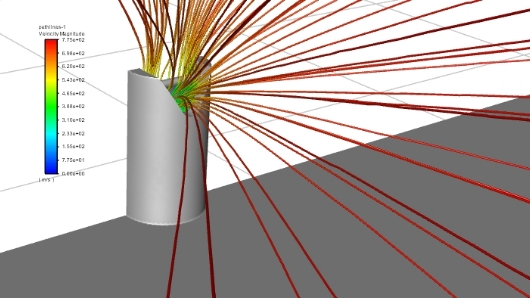

– Simulation in Kooperation mit dem Center for Wind Power Drives (CWD) der RWTH Aachen, durch Hrn. Prof. Jacobs, Hrn. Dr. Schelenz und Hrn. Dipl. Ing. Witter.

– Neutronenstrahluntersuchung im Auftrag der VSR durch Hrn. Dr. Hofmann von der Forschungs-Neutronenquelle Heinz Maier-Leibnitz an der TU München in Garching.

Der gewünschte Nachweis sollte erbracht werden, indem zunächst eine Simulationsleitlinie ermittelt und nachfolgend die Ergebnisse mit denen der Neutronenstrahluntersuchung verglichen werden, u.a. um eine Methode zur rechnergestützten Analyse der optimierten Eigenspannungsreduzierung von Bauteilen durch Vibrationsentspannung zu entwickeln.

So realitätsnah wie möglich, wurde als Probenwerkstoff der gängige Baustahl S355 gewählt. Die Erstellung und Handhabung der Proben erwies sich im Laufe des Projekts als sehr aufwändig, da jegliche Beeinflussung von außen zu einer Veränderung des Eigenspannungszustands hätte führen können.

Die optimale Positionierung der Proben sowie die Einbringung der Vibrationsenergie wurden durch das Simulationsmodell ermittelt; die Proben wurden dann anhand der Vorgaben in Garching aufgebaut, durchstrahlt, vibrationsbehandelt und erneut durchstrahlt. Zeitgleich wurde in Aachen die Simulationsrechnung durchgeführt.

Bei Untersuchung der speziellen Proben, die zur Steigerung des Eigenspannungspotentials geschweißt waren, konnten anhand der Neutronenstrahlmessung keine belastbaren Beweise für große Unterschiede zwischen den Spannungszuständen vor und nach der Vibrationsbehandlung erbracht werden. Als Grund hierfür wird vom überlagernden Einfluss der natürlichen Relaxation über die vergleichsweise lange Zeit ausgegangen, die für die Gesamtabwicklung des Versuches in Duisburg, Berlin und München notwendig war, sowie den äußeren Einflüssen während der notwendigen Transporte.

Dagegen ergab die Simulation auf Basis der tatsächlich eingestellten Randbedingungen (Schweißzusatzwerkstoff und –geschwindigkeit, Werkstoffkenndaten, Anregungsrichtung, -amplitude und –frequenz) das eindeutige Ergebnis, dass durch eine Vibrationsbehandlung die unliebsamen Eigenspannungen abgebaut werden.

Bei der abschließenden, vergleichenden Untersuchung einer vibrationsentspannten und einer spannungsarmgeglühten Probe zeigte sich sogar, dass bei dem gewählten Werkstoff die Eigenspannungen durch die Vibrationsbehandlung besser reduziert worden waren als durch das Glühen.